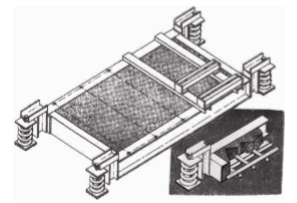

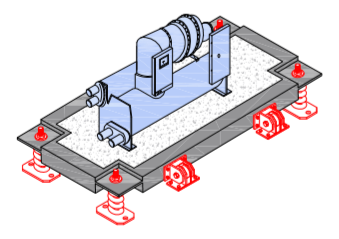

INERTIA POURING FRAME (IPF)

Inertia Pouring Frame has been developed for use with machines which produced high level of Vibration or those which are subjected to external forces or are simply unstable when mounted directly on high deflection/low stiffness helical spring or rubber Mountings for giving extremely high degree of vibration isolation without excessivemotion.

Vibration attenuation is dependent on base rigidity as well as Isolator deflection. If the base becomes distorted because of weight distribution, belt pull or the torque introduced by a direct drive, the equipment will wear out more quickly and vibrate excessively because of the loss of the alignment.

Base is another difficulty RESONANCE that can result from poor frame construction, If base members are light and long, they will tend to at low RESONATE frequencies that may be sympathetic or close to the operating speeds of the mountede quipment.

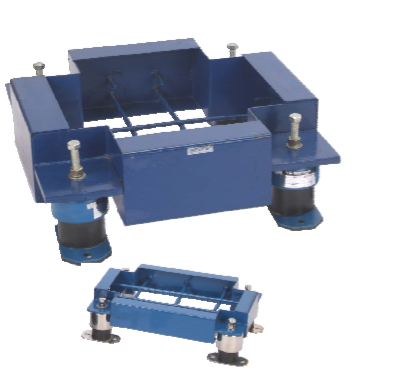

The Frame is of fully welded construction with reinforcing bars and can be straight away filled at site with concrete to become rigid floating concrete platform.

The inertia weight of the concrete will also reduce the

operating amplitude of

equipment.

Viscous Damper can be incorporated to further control motion during transient

conditions such as machine run-down and machinefaults.

Height saving brackets can be used to further lower the Centre of Gravity for

better stability.

TYPICAL APPLICATIONS

Installation Gallery

Unlock Your Potential with Expert Guidance

We’re dedicated to providing

custom-engineered

solutions that enhance efficiency and performance.

Let’s work together to achieve your project goals seamlessly.