Challenge:

Indian Oil Corporation Limited R&D Centre at Faridabad was experiencing problems with the continuous operation of their Railway Axle Testing Machine, used to test lubrication of Railway Axle Bearings, which help in smooth operation of trains. Whenever the Grease Testing machine was in operation, the complete floor of the building was experiencing heavy vibrations generated by the machine. Due to this, the adjacent labs with high-precision Electron Microscopes were not able to work.

Results:

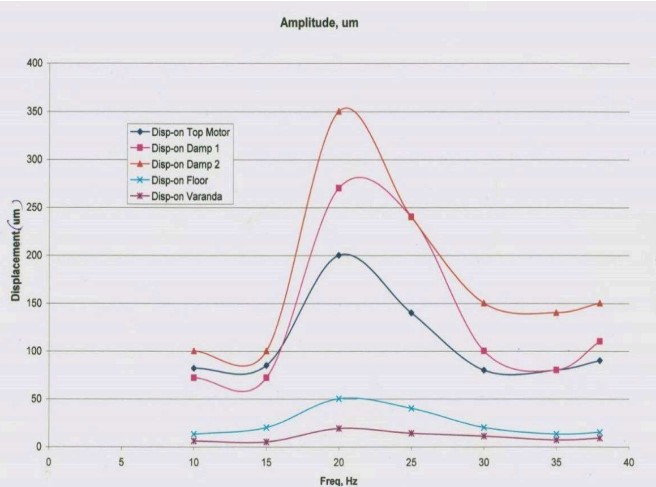

Calculated results showed 90% isolation of vibrations generated by the Railway

Axle

Testing Machine.

However, after measurement by a third party, it was established there was a 98%

reduction in vibration levels on the building floor.

Measured results of before and after installation of Resistoflex Vibration Isolation System at IOCL Faridabad.