Expansion Joints Enhance Safety and Efficiency in Industrial Systems

How Expansion Joints Enhance Safety and Efficiency in Industrial Systems

Introduction

When it comes to running industrial systems smoothly and safely, expansion joints play a very important role. they are one of the most essential components in order for projects to be successful across different industries and for enhancing the efficiency of infrastructure.

The Role of Expansion Joints in Industrial Systems

Imagine a pipeline carrying high-temperature fluids or a bridge expanding under the summer sun. Without room to breathe and flex, these systems would crack under pressure—literally. In such cases, expansion joints are the solution designed to absorb movement, reduce stress, and prevent damage.

Enhancing Safety: A Top Priority

In industries like construction, automotive, and heavy machinery, any failure could have catastrophic consequences. Expansion joints enhance safety in several key ways:

- Minimizing Stress: By absorbing movement and vibrations, they prevent fractures, leaks, and other structural issues.

- Preventing Overpressure: In systems like pipelines, expansion joints relieve excess pressure, ensuring safe operations.

- Ensuring Stability: They keep infrastructure stable during seismic activities or sudden shifts, offering peace of mind even in unpredictable scenarios.

Boosting Efficiency: Saving Time and Money

Efficiency is another area where expansion joints shine. As someone who values streamlined operations, I appreciate how they help systems run without a hitch. Here’s what I’ve observed:

- Reduced Downtime: Expansion joints protect equipment from wear and tear, reducing maintenance needs and unplanned shutdowns.

- Energy Savings: By isolating vibration and noise, they improve the efficiency of systems like HVAC units and pipelines.

- Increasing Longevity : Properly installed expansion joints extend the service life of expensive infrastructure, maximizing return on investment.

Applications Across Industries

One of the things I find most fascinating about expansion joints is their versatility. No matter the industry, there’s a good chance these components are working behind the scenes. Here are some examples:

- Automotive Manufacturing: Reducing vibration in engines and exhaust systems.

- Construction and Infrastructure: Absorbing movement in bridges, tunnels, and pipelines.

- HVAC Systems: Managing temperature changes in air conditioning ducts.

- Railways and Metro Systems: Ensuring smooth operations despite constant movement and stress.

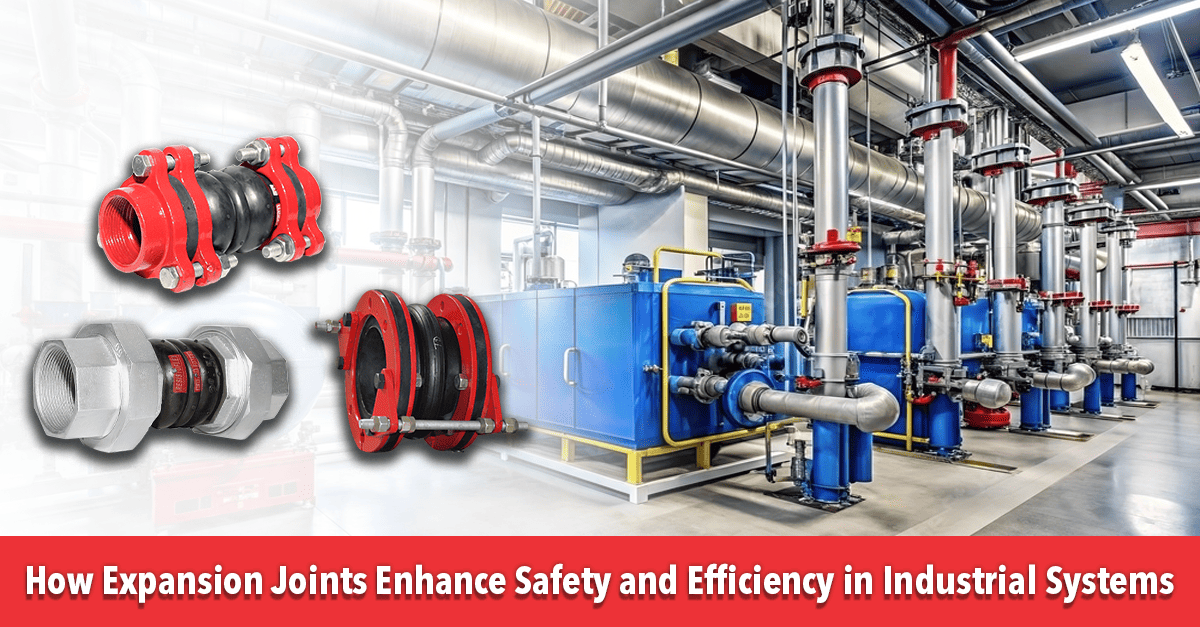

Flexible Rubber Connectors from Resistoflex make a significant difference in many of these scenarios. For instance:

- Flexible Rubber Connectors with Standard Union Ends: Perfect for managing vibrations and handling temperature changes in pipelines.

- Flexible Rubber Connectors with Flanged Union Ends: Provide excellent sealing and alignment in systems prone to misalignment or pressure changes.

Sustainability Benefits

Using expansion joints isn’t just smart—it’s sustainable. By reducing material fatigue and extending equipment life, these components help lower waste and resource consumption. They let you do more with less, which is good for both your budget and the environment.

Choosing the Right Expansion Joints

Of course, not all expansion joints are created equal. Selecting the right type for your system’s needs is critical. When I’m evaluating options, I consider factors like:

- Temperature and Pressure Ranges

- Material Compatibility

- Movement Requirements

- Installation and Maintenance Ease

Conclusion

The importance of expansion joints in enhancing safety, efficiency, and sustainability cannot be denied. If you’re in industries like construction, manufacturing, or energy, I believe these small yet mighty tools deserve a place in your operations. So, the next time you plan a project, don’t overlook these essential allies—your systems and your bottom line will thank you.